Technology

Wattera is a modern, world class facility for injection molded plastics located in Juarez Mexico.

Service

We pride ourselves in offering the highest level of customer service, and tool design capability.

Capabilities Include

30 MOLDING MACHINES (60T TO 1000T+)

Injection Molding

Full-service of production injection mold tooling.

Painting

We are able to paint plastic components.

Pad Printing

Our equipment produces highest quality images.

Laser Etching

Permanent direct product and part marking.

Vacuum Metalization

Years of experience in vacuum metalizing and coating.

ISO 9001 : 2015 certified · IATF 16949:2016

The IATF 16949:2016 standard, which contains all of ISO 9001:2015, along with automotive sector-specific requirements from the American QS-9000, German VDA 6.1, French EAQF and Italian AVSQ quality standards, places major emphasis on customer satisfaction and promises to lay the foundation for an exceptional line of products.

The standard affects companies that manufacture or supply components and other products to the American, German, French, Italian, British, Japanese and other automotive industries

We are IATF 16949 certified.

WATTERA IS MODERN, WORLD CLASS FACILITY FOR INJECTION MOLDED PLASTICS

Secondary Processes

Capabilities Include : Injection molding, painting, laser etch, and other secondary processes.

WATTERA TOOLING

Infrastructure

Our engineering expertise allows for smooth process for manufacturability as per customer concerns!

Pad Printing

Laser Etching

Vacuum Metalization

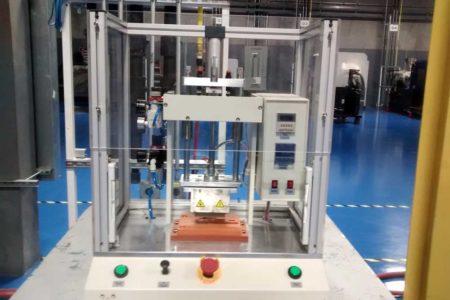

Heat Staking

Painting

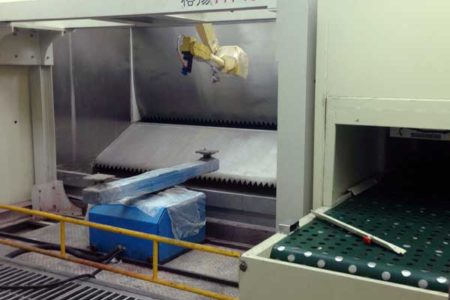

Ultrasonic Welding

Assembly

Tooling

Molding Captabilities

We offer a full range of engineering expertise from mold design and design for optimal manufacturability. Wattera has manual, semi-automated, and fully automated machines capable of:

Overmolding

Insert Molding

Inner Mold Labelling

Closed Loop Injection Molding

Double Shot Molding

High Pressure Structural Foam Molding

Gas-assist Molding

Crystal Clear Molding (Bezels, Light-pipes, lenses, etc…)

MACHINE

CINCINNATI MILACRON

CINCINNATI MILACRON

CINCINNATI MILACRON

KAWAGUCHI

SUMITOMO

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

Haitian

TONNAGE

85

85

165

190

260

600

280

280

280

280

200

200

160

160

160

160

120

120

90

90

90

Secondary Processes

Laser Etching

Vacuum Metalization

Heat Staking

Painting

Ultrasonic Welding

Assembly

Assembly

Tooling

Quality and Metrology Equipment

EQUIPMENT

DIAL INDICATOR DIGITAL

CMM GLOBAL CLASSIC

HUMIDITY ANALYZER

CALIPER DIGITAL

ELECTRONIC SCALE

HUMIDITY

TEMPERATURE

GAGE BLOCK

WEIGHT SCALE

BLOCK GAGE

SPECTROMETER

PIN GAGE

PIN GAGE

PIN GAGE

PIN GAGE

PIN GAGE

PIN GAGE

PIN GAGE

PIN GAGE

MANUFACTURER

MITUTOYO

BROWN &SHARPE

DSC

FOWLER

AND A&D

EXTECH

EXTECH

MITUTOYO

ULINE

MITUTOYO

X-RITE

FOWLER

STARRETT

MEYER

VERMONT

MEYER

MEYER

FOWLER

FOWLER

EQUIPMENT

DIAL INDICATOR DIGITAL

DIAL INDICATOR ANALOGO

DIAL INDICATOR ANALOGO

HOLE GAGE

RADIO GAGE

RADIO GAGE

DEPTH MICROMETER

DEPTH MICROMETER

DEPTH MICROMETER

DEPTH MICROMETER

MICROMETER

HEIGHT GAGE

PIN GAGE

PIN GAGE

PIN GAGE

PIN GAGE

PIN GAGE

DIAL INDICATOR DIGITAL

MANUFACTURER

MITUTOYO

CDI

FOWLER

START

STARRETT

STARRETT

STARRETT

FOWLER

STARRETT

STARRETT

STARRETT

MITUTOYO

VERMONT

MEYER

VERMONT

VERMONT

VERMONT

MITUTOYO